Advantages of reusing manure

- The recycled bedding material is comfortable for the cow and bacteria-free

- No more expensive purchase of bedding material

- The machine can be operated and monitored remotely

- Fast Return on Investment

- The process provides significant CO2 reductions

- The system is an excellent combination with a biogas installation

Choose the BeddingMaster from Mavasol

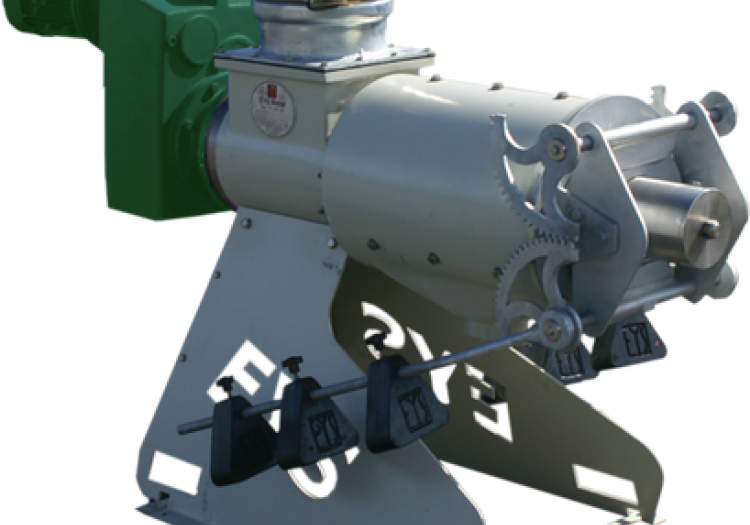

The BeddingMaster has been developed by combining age-old composting techniques and the knowledge and experience of Daritech. The BeddingMaster converts cow manure into comfortable and hygienic bedding material. The verified and controlled composting process allows manure to be reused in livestock cubicles. Clean and affordable bedding, pleasant for humans and animals.

Manure is a valuable product that can be used to earn money in livestock farming. With the BeddingMaster, the manure is efficiently converted into a valuable product for the farmer and a high level of comfort and health for the cows. Mavasol helps dairy farmers to comply with environmental regulations for their manure. Profit is generated by reducing fertilizer processing costs and increasing fertilizer yield.

We help you on your way to a circular revenue model

Circular economy is becoming increasingly important. By properly handling raw materials and increasing the efficiency of the processes, the carbon footprint can be significantly reduced while saving money for the dairy farm. The BeddingMaster helps livestock farmers to tie the end of the chain to the beginning.

How the Manure Composting process works

Don't waste time and money on sawdust and shavings, Mavasol has the sustainable solution. Bedding developed for dairy farmers who use recycled manure as bedding.

STEP 1: 35% Dry matter

The slurry is pushed out of the boxes and collected in a pit. With the Screw Press Separator specially designed by Daritech, the water is drained from the manure and 36% dry matter remains. This is the ideal raw material for the BeddingMaster. The solid fertilizers are fed into the BeddingMaster through a fixed opening.

STEP 2: Composting by using the present bacteria

The beauty of composting solid manure is that the aerobic bacteria, which consume the organic matter, are already in the solids thanks to the dairy cows. These bacteria start the composting process.

STEP 3: With proper air supply, rotation and a controlled temperature

Once inside the BeddingMaster, the bacteria multiply, completing the work started in the cows' stomachs. A fan pulls air through the drum, providing an ample supply of air, which mixes with the solids tumbling through the drum's rotation. Within hours, the activity of the bacteria raised the temperature above 65°C (150ºF). Due to the rotation process, the temperature in the machine and the aeration, the manure is completely composted in 12 to 24 hours.

STEP 4: Resulting in a suitable bedding material of compost

The hygienic and dry material that comes out of the BeddingMaster is dry and scent-free. The material is comfortable for cows and can be used directly as bedding material. In addition, the end product can also be used as a soil improver.

The result is a hygienic, scent free and dry beddingmaterial

Thanks to the clean end-product and thus a reduction of bacteria in the stables, the health of the cow is improved. Our manure composting method is now being used on several dairy farms in Europe. In many of these projects, the BeddingMaster is used in combination with a biogas installation. First of all, nutrients are extracted from the manure and other organic waste products and used to generate electricity. After this, the residual product from the biodigester goes to the BeddingMaster to be composted, so that it can be reused as compost or as circular box litter.

Our solutions for manure management

A proven composting technology for dairy farmsWith years of reliable and documented BeddingMaster success on dairy farms around the world, Mavasol offers a flexible in-vessel composter with a proven track record of meeting your manure recycling needs. The BeddingMaster is available in a variety of sizes and configurations to suit your needs. Always a complete overview of the savings and a 3D CAD-design in advanceThe BeddingMaster is a largely part of Daritech's manure processing systems. In addition to the BeddingMaster, these mainly consist of separators, roller presses and conveyor systems. Mavasol designs custom solutions for the cost-effective processing of manure. We make optimal use of existing pits and pumps, if this is possible. We always make a design in 3D CAD to show you how the system will fit on your property and which permits may be required. We complete the quotation with a savings overview of the costs, the payback period and the CO2 reduction that the system produces. |